While 2021 saw the major manufacturers racing toward ever higher resolutions and larger print sizes - trends which will continue into the first half of 2022 - I believe that some of the fundamental focuses will begin to shift in 2022. And here's how:

While DLP technology in 3D printing has existed for some time, it has largely existed only on high-dollar commercial machines. Anycubic's Photon Ultra seeks to change that. Kickstarter-priced as low as $399 ($599 retail) - the Ultra will be the first printer to bring DLP onto the workbench of home hobbyists.

So surely the race to even higher resolutions will continue full speed ahead, right? My guess is no. In a world where the manufacturers have been locked in a race to ever higher resolutions, why would they stop focusing so heavily on resolution? The answer is simply one of diminishing returns - the resolution of hobbyist resin printers is quickly reaching the point where any further improvements will be indistinguishable to the naked eye.

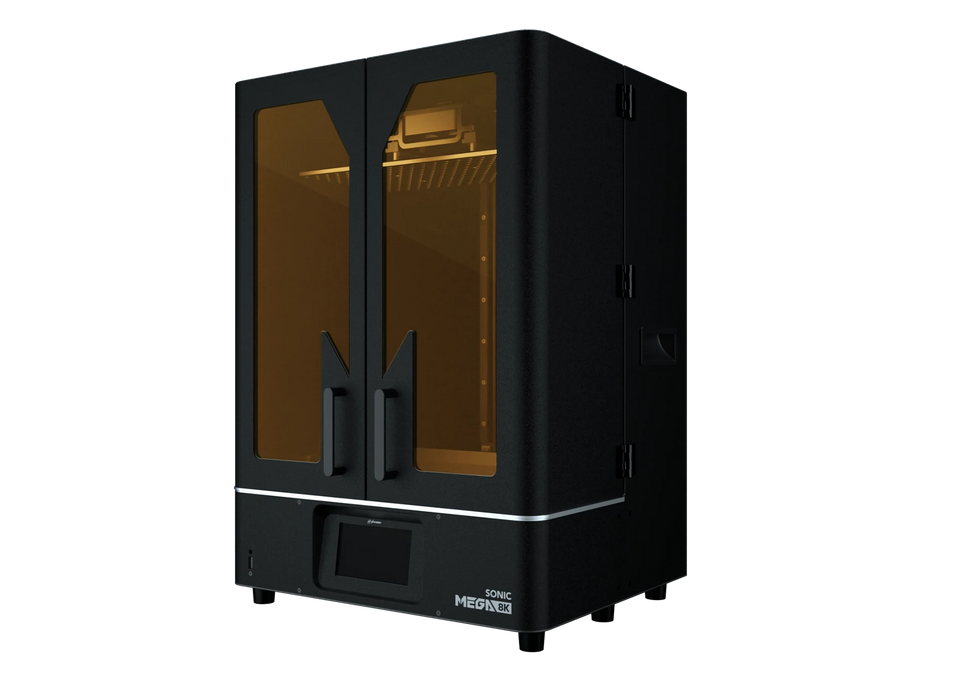

Printer size is another area where a limit seems to be fast approaching. The newest, largest printers offer huge capability to the hobbyist printer, but practical limitations such as resin capacity, printer size and FEP film capabilities mean that consumer-grade printers are unlikely to get much bigger.

With resolution and print size maxed out, 2022 will see the manufacturers starting to compete instead on print speed. Print speed still remains one of the biggest limitations of resin printing. While today's mono-screened printers offer much greater speeds over older RGB printers, there still is room for improvement in this regard.

In addition, the post-processing remains a turn-off for many would-be buyers of resin printers. Many people see the mess, fumes and extra work involved in cleaning prints and removing the supports as a barrier to purchase. As such, I think the printer manufacturers will address these concerns to make resin printing easier for the average hobbyist.

These two factors lead to what I think will be the next big thing for 2022:

For 2022, I expect at least one of the big manufacturers to get in on the top-down game. If I had to bet on which one, my money would be on Anycubic. After all, Phrozen is still in catch-up mode trying to fulfill Sonic Mini 8K orders, and Elegoo will be tied up building and shipping pre-ordered Jupiter units. Anycubic on the other hand has the DLP technology they've already invested in for the Photon Ultra which would be an ideal type of image projection for top-down printing.

While Chitu Systems eventually walked back their line and stated they would make their development code available to other companies, the whole debacle highlighted how little true choice exists in the young resin printing market. After all, the printers from all the major manufacturers use hardware developed by Chitu. As it stands now, the home hobbyist resin 3D printing market is a de facto monopoly, leaving all the power in Chitu's hands. Without vigorous competition in the market, Chitu Systems has little impetus to continue improving their products, both on the hardware and software side.

Some enterprising individuals and startups have set out to develop an open source approach to resin 3D printing which could help stabilize the market and prevent hobbyists from bearing the brunt of one company throwing around its will, or worse sitting on its laurels. Instead of developing new chipsets and circuit boards from the ground up, a lot of this open source development seems to be taking place using open source micro computers such as RaspberryPi.

My wish for 2022 is that a truly viable and accessible open-source printing architecture makes a big enough presence in the market to at least put Chitu on notice that ours is a community of makers and problem solvers who won't just idly sit by and accept bad products or bad business.